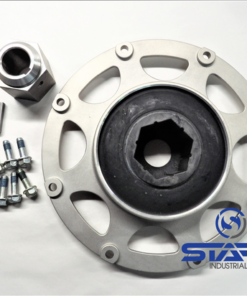

Centamax 240 Drive Coupler | Heavy-Duty Flexible Industrial Coupling

$890.00

The Centamax 240 Drive Coupler is a heavy-duty flexible coupling engineered for high-torque power transmission, vibration damping, and shaft misalignment compensation in industrial machinery, compressors, generators, and engine-driven equipment. Manufactured as part of the Centamax product line by CENTA, this coupling is designed to deliver reliable performance, reduced torsional vibration, and long service life in demanding continuous-duty applications. Supplied by Stark Industrial Products, with fast shipping available on stocked units.

The Centamax 240 Drive Coupler is a precision-engineered elastomeric coupling designed for industrial and power transmission systems where vibration control, torque stability, and mechanical protection are critical. Centamax couplings are widely used across compressors, generator sets, pumps, and heavy industrial machinery due to their proven ability to absorb torsional shock and compensate for shaft misalignment.

This coupling connects the prime mover—such as an electric motor or internal combustion engine—to the driven equipment, allowing torque to be transmitted smoothly while isolating vibration. By reducing torsional oscillations, the Centamax 240 helps protect bearings, shafts, gearboxes, and driven components from premature wear and fatigue.

Built for high-load and continuous-duty operation, the Centamax 240 is well suited for harsh industrial environments where reliability and uptime are essential.

Key Features and Benefits

-

CENTA Centamax OEM Coupling – Manufactured to original Centamax engineering standards

-

High Torque Capacity – Designed for demanding industrial and power generation applications

-

Elastomeric Flexible Design – Absorbs torsional vibration and dampens shock loads

-

Smooth, Backlash-Free Torque Transmission – Ensures stable power transfer

-

Misalignment Compensation – Accommodates angular, axial, and parallel shaft misalignment

-

Heavy-Duty Construction – Suitable for continuous-duty industrial environments

-

Low Maintenance Operation – Lubrication-free design with long service intervals

Functional Design and Performance

The Centamax 240 coupling uses a high-performance elastomer element integrated with precision-machined steel components to create a torsionally flexible shaft connection. This design allows the coupling to act as a mechanical buffer, absorbing vibration and transient torque spikes before they are transmitted into the drive train.

In applications such as rotary screw air compressors and generator sets, torsional vibration is a leading cause of bearing wear, shaft fatigue, and alignment drift. The elastomer element within the Centamax 240 reduces these forces, improving mechanical stability and extending the service life of connected components.

The coupling also compensates for minor installation tolerances and thermal expansion that naturally occur during operation. This helps maintain proper alignment under varying load and temperature conditions without introducing excessive stress into the system.

Applications and Compatibility

The Centamax 240 Drive Coupler is commonly used in a wide range of industrial and power transmission applications, including:

-

Rotary screw and piston air compressors

-

Generator sets and engine-driven equipment

-

Industrial pumps and motor assemblies

-

Gearbox-driven power transmission systems

-

Heavy industrial and processing machinery

The Centamax 240 is suitable for both OEM installations and replacement applications where a Centamax-series coupling is specified.

Technical Specifications (General)

-

Model: Centamax 240

-

Manufacturer: CENTA

-

Coupler Type: Flexible elastomeric drive coupler

-

Product Line: Centamax

-

Function: Torque transmission with vibration damping

-

Misalignment Capability: Angular, axial, and parallel

-

Operating Environment: Industrial and power transmission systems

-

Maintenance: Lubrication-free; inspect during routine service intervals

Performance Advantages

The Centamax 240 Drive Coupler delivers stable, vibration-controlled torque transfer that improves reliability across the entire drive system. By isolating torsional vibration, it reduces mechanical noise, limits wear on bearings and shafts, and helps prevent costly downtime caused by premature component failure.

Compared to rigid couplings or generic flexible couplers, Centamax couplings are engineered with elastomer characteristics optimized for industrial drive requirements. This ensures predictable damping behavior, consistent torque transfer, and long-term durability under fluctuating loads.

Using the correct Centamax coupling helps preserve original equipment performance, alignment accuracy, and operational efficiency.

Why Choose Stark Industrial Products

Stark Industrial Products supplies OEM and OEM-spec industrial couplings used in compressors, generators, and power transmission systems. Every coupling we offer is selected for durability, performance, and real-world application compatibility.

-

OEM and OEM-spec industrial couplings

-

Fast order processing and secure packaging

-

Knowledgeable technical support

-

Trusted supplier for industrial power transmission components

If you need assistance confirming shaft sizes, hub configurations, or compatibility for your Centamax 240 application, our team is ready to help.

| Weight | 20 lbs |

|---|

Related products

Sullair Air Compressor Parts

046999 Sullair OEM Drive Coupler | Genuine High-Performance Compressor Coupling

Sullair Air Compressor Parts

250041-801 Sullair OEM Drive Coupler | Genuine High-Performance Compressor Coupling

Sullair Air Compressor Parts

250031-457 Sullair OEM Drive Coupler | Genuine High-Performance Compressor Coupling

Air Compressors

42HE180 Replacement OEM Drive Coupler | Genuine High-Performance Compressor Coupling

Sullair Air Compressor Parts

250015-397 Sullair OEM Drive Coupler | Genuine High-Performance Compressor Coupling

Ingersoll Rand Air Compressor Parts

36063261 Ingersoll Rand OEM Drive Coupler | Genuine High-Performance Compressor Coupling

Sullair Air Compressor Parts

LCD-0075-48-C Sullair OEM Drive Coupler | Genuine High-Performance Compressor Coupling

Ingersoll Rand Air Compressor Parts

LCD-0075-47-C OEM Drive Coupler | Compressor Motor-to-Air-End Coupling