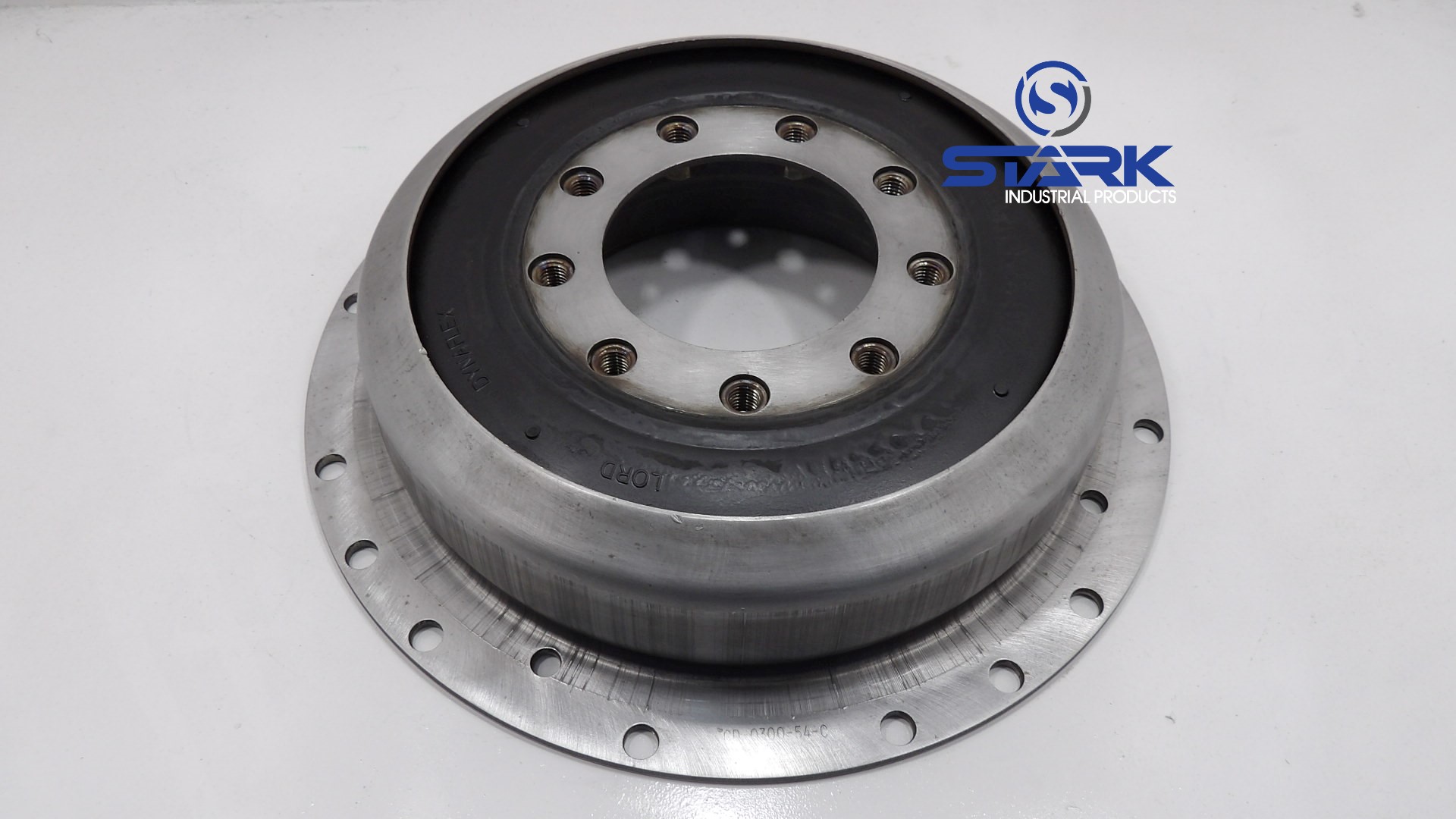

TA20453 John Deere OEM Drive Coupler | High-Performance Compressor Coupling

$950.00

The TA20453 John OEM Drive Coupler is a genuine elastomeric coupling engineered for smooth torque transfer, precise alignment, and vibration control in compressor systems. Built to OEM standards with reliable performance and fast shipping.

2 in stock

TA20453 John Deere Torsional Damper Coupler is an OEM-grade drive coupler engineered for smooth torque transfer, controlled vibration, and precise shaft alignment in rotary screw compressors and industrial drive systems. This page is written for technicians and buyers who need clear, practical details to support maintenance planning, quick sourcing, and reliable day-to-day operation.

The TA20453 John Deere OEM drive coupler links the drive motor to the compressor air-end while compensating for minor angular and parallel misalignment. The elastomer interface isolates vibration, reduces stress on bearings and seals, and supports stable compressor performance across varied duty cycles.

Key benefits include OEM-level construction, a flexible element that absorbs torsional shock, durable hub materials suited for industrial environments, and maintenance-free operation with no lubrication required. This style of coupler supports predictable uptime and consistent performance in continuous-duty applications.

Typical uses include rotary screw compressors, portable compressor units, motor-to-air-end couplings, and general industrial equipment requiring vibration-damped torque transmission. As an OEM-matched component, it installs directly in place of factory couplers, helping restore original equipment balance and alignment behavior.

Why it matters: a correctly selected and installed coupler protects rotating assemblies by smoothing torque delivery, reducing mechanical noise, and limiting the transmission of harmful loads. Using genuine OEM or OEM-equivalent components helps maintain compressor reliability and prevents vibration issues associated with mismatched substitutes.

Installation overview: clean and deburr shafts, verify key fit, align hubs within manufacturer limits, and torque hardware evenly. After start-up, confirm vibration is within baseline. Most premature failures trace back to misalignment or over-compression of the elastomer element, so careful alignment and torque practices are critical.

Maintenance overview: inspect at planned intervals for cracking, glazing, or deformation of the flexible element. Track vibration trends and replace proactively as readings drift. Keeping a spare on hand enables quick changeouts during scheduled service windows and minimizes downtime.

Sourcing & quality: Stark Industrial Products supplies verified OEM and OEM-equivalent couplers for service teams, rebuild shops, and facility maintenance groups. Orders are packed to protect elastomer integrity during shipping, and common compressor sizes are kept in stock for fast turnaround.

Related resources: Shop all parts, Search this SKU on our site, Browse by brand.

The TA20453 coupling supports continuous-duty operation and helps extend component life by moderating torsional ripple during starts and load changes.

Facilities standardize on this style of flexible coupling to simplify alignment steps, tolerate minor thermal growth, and stabilize running conditions under variable loads.

Predictable damping characteristics contribute to lower vibration levels and fewer unscheduled stops, particularly in fleets where compressors operate across mixed duty cycles.

When installed with proper torque and alignment, the assembly reduces transmitted stress, protecting motors, air-ends, and downstream rotating elements from premature wear.

Keeping a service-ready spare coupler on the shelf allows proactive maintenance during planned outages and reduces overall cost of ownership.

Technicians often include coupler inspection with belt checks, bearing lubrication schedules, and alignment verification to maintain a clean vibration baseline.

Consistent part selection across similar machines simplifies inventory management and makes troubleshooting faster for field and plant maintenance teams.

By prioritizing a coupler with the correct geometry and elastomer characteristics, teams can preserve compressor efficiency and extend mean time between overhauls.

In environments with variable frequency drives, the right elastomer stiffness helps smooth torque ripple and reduces audible noise from the drivetrain.

Adopting a preventative replacement interval for the coupler aligns well with other planned service tasks and minimizes the risk of unplanned downtime.

The TA20453 coupling supports continuous-duty operation and helps extend component life by moderating torsional ripple during starts and load changes.

Facilities standardize on this style of flexible coupling to simplify alignment steps, tolerate minor thermal growth, and stabilize running conditions under variable loads.

Predictable damping characteristics contribute to lower vibration levels and fewer unscheduled stops, particularly in fleets where compressors operate across mixed duty cycles.

| Weight | 25 lbs |

|---|

Related products

John Deere Earth Moving Equipment Parts

LCD-0400-44-D Lord OEM Drive Coupler | Genuine High-Performance Compressor Coupling

Atlas Copco Air Compressor Parts

1619-6469-04 Atlas Copco OEM Drive Coupler | Genuine High-Performance Compressor Coupling

Atlas Copco Air Compressor Parts

1604-0761-00 Atlas Copco OEM Drive Coupler | Genuine High-Performance Compressor Coupling

Ingersoll Rand Air Compressor Parts

35834779 Ingersoll Rand OEM Drive Coupler | Genuine High-Performance Compressor Coupling

Ingersoll Rand Air Compressor Parts

36774321 Ingersoll Rand OEM Drive Coupler | Genuine High-Performance Compressor Coupling

Sullair Air Compressor Parts

45672 Sullair OEM Drive Coupler | Genuine High-Performance Compressor Coupling

John Deere Earth Moving Equipment Parts

RE222311 John OEM Drive Coupler | Genuine High-Performance Compressor Coupling

John Deere Earth Moving Equipment Parts

RE45382 John OEM Drive Coupler | Genuine High-Performance Compressor Coupling